From Columbia to The Holy Land

The skyline of Tel Aviv has changed considerably since I first visited there in 2008. The explosive traffic condition is felt as one rides around the city and along Highway 6, the Cross-Israel Highway. There is an acute need to expand the public transportation network in alleviating congestion while accommodating new demands. The rebuilding of “Ottoman” Eastern line that will run parallel to Highway 6 is such an effort.

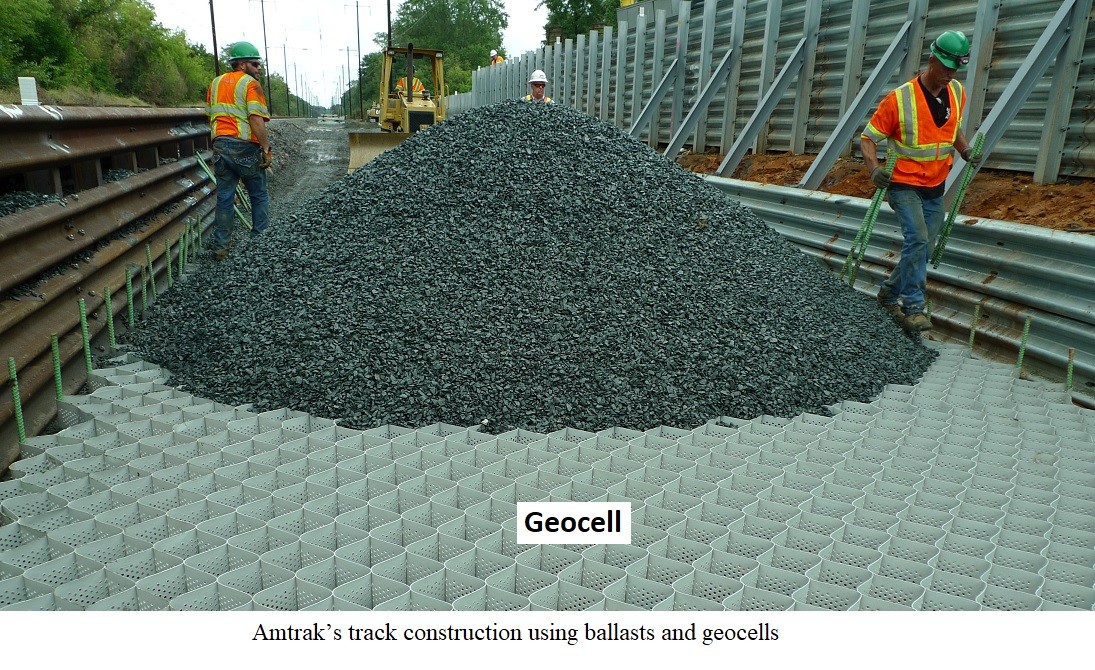

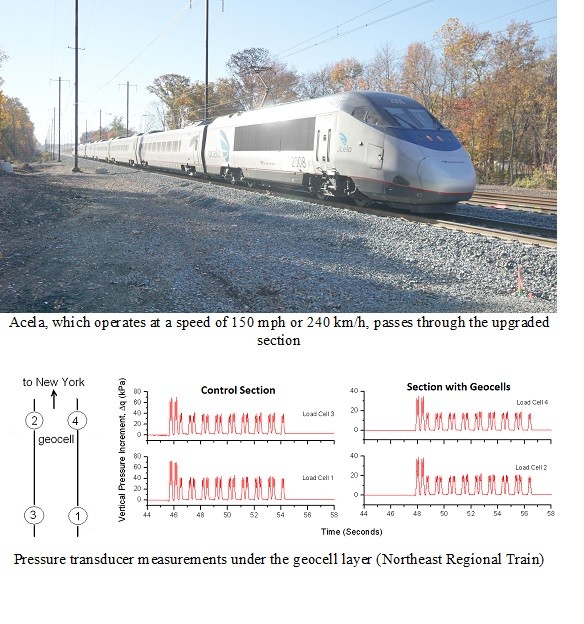

We started a research program with PRS Geo-Technologies (Tel Aviv) on the seismic studies of soil retaining walls reinforced by geocells in 2006, and then on reinforcing railway ballast embankment using geocells. PRS Geo-Technologies is a pioneer in manufacturing polymeric alloy materials used to fabricate geocells. A series of large-scale monotonic and cyclic loading tests on reinforced ballasts were conducted at Carleton Laboratory. We also used the test results to validate numerical models. The geocell was found effective in restraining the deformations of ballasts. In 2015, with the support of Federal Railway Administration and Amtrak, this technology was implemented to upgrade a 300-m section of railroad found on soft ground along Northeast Corridor (Washington DC-New York). We instrumented the section with earth pressure transducers installed under the geocell layer. Compared to the control section, the geocells reduced the vertical pressure by more than half. The long-term monitoring over a period of 6 years, still ongoing, showed very satisfactory performance. The maintenance cycle for the ballasts was prolonged significantly.

Israel has unique geological conditions, with some parts having problematic soils. With a proven performance through the laboratory and field studies, the technology is now adopted for the new railroad construction along the Eastern line. The line links Hadera and Lod, bypassing the Ayalon railway bottleneck in Tel Aviv. Danya Cebus, a major construction company is involved in 20 km (Section B) of the line using geocells. Similar technologies are expected to be implemented at other parts of the line under the supervision of Netivei Israel (National Roads Company) and Israel Railways. This is an amazing development because new reinforced soil technologies are usually implemented in rather small sections as a start, say less than a few hundred meters, but here we have it from a small step into a big leap stretching over 20 km. Recently, plate load tests have been done at the site to validate the design.

Solid research is the driving force behind a proven technology. We welcome your support to continue with this research program.